In the evolving world of pharmaceutical compounding, regulatory compliance has shifted from a box to check to a line in the sand. As USP <797> and <800> standards become more rigorously enforced, the organizations thriving today aren’t just meeting these requirements—they’re designing their operational strategies around them.

Yet with this shift comes a complex reality: building compliant infrastructure isn’t easy, fast, or always feasible within the constraints of capital budgets, site limitations, or production timelines. That’s why a growing number of industry leaders are embracing a new approach—treating cleanroom compliance as a flexible, scalable capability rather than a fixed asset.

Regulatory Pressure is Reshaping Cleanroom Strategy

USP <797> and <800> reflect a broader regulatory trend—one that emphasizes not only drug quality and environmental controls, but also personnel safety, containment architecture, and continuous monitoring. Facilities that once got by with basic sterility protocols are now required to prove, document, and sustain compliance in far more granular ways.

This shift isn’t just technical—it’s strategic. Compliance has become a business driver. The ability to respond quickly to regulatory changes or adjust operations based on new drug classifications is a marker of operational maturity. Facilities stuck in rigid infrastructure models are often slower to respond, less able to pivot, and more exposed to risk. Modular cleanrooms turn compliance into an agile capability, scaling up or down, reconfiguring, or relocating without lengthy construction projects or large capital investments.

Flexibility is the New Compliance Advantage

We’re entering a new era—one where adaptability is synonymous with regulatory strength. The old model of fixed cleanroom infrastructure is giving way to a more dynamic mindset: modular, self-contained, and precisely aligned with regulatory needs. Facilities are asking a different question now—not “How can we build for compliance?” but “How can we stay compliant while staying flexible?”

This is especially true for organizations handling both sterile and hazardous compounding. Integrating USP <797> and <800> requirements under one roof isn’t just a design challenge—it’s an operational balancing act. It requires nuanced airflow strategies, pressure differentials, zoning, and validated workflows that can withstand regulatory scrutiny. Being able to configure these environments quickly, or relocate them entirely, opens new pathways for innovation and compliance.

The Myth of Incompatibility

At first glance, USP <797> and <800> appear to have opposing goals. One protects sterility, the other ensures containment. One requires positive pressure, the other mandates negative pressure. But, in reality, their requirements don’t conflict—they complement, provided they’re thoughtfully engineered.

USP <797> defines the environmental conditions required for sterile drug compounding, focusing on the prevention of microbial contamination. USP <800>, on the other hand, is centered on the safe handling of hazardous drugs, emphasizing staff protection, and containment of particulates and vapors. When sterile hazardous drugs are involved—a growing category—both sets of standards must be met simultaneously.

This is entirely achievable when cleanrooms are designed as ecosystems of controlled zones, not isolated rooms.

The Architecture of Integration

Successfully combining USP <797> and <800> requires more than adding walls—it requires a layered approach to zoning, airflow, and monitoring. Here’s how leading facilities are making it work:

- Nested Pressure Environments: By creating a negative pressure compounding room for hazardous drugs inside a larger positive pressure sterile buffer suite, facilities can satisfy both containment and sterility goals. Carefully calibrated pressure differentials keep clean air flowing in and hazardous materials from leaking out.

- Shared Anterooms, Segregated Functionality: A negative-pressure hazardous buffer room served by a shared ISO 7 anteroom that is positive to surrounding spaces; non-hazardous sterile compounding occurs in a separate positive-pressure ISO 7 buffer also served by that anteroom.

- Dedicated Ventilation and Exhaust: While sterile and hazardous areas may share physical proximity, they must have independent HVAC systems—particularly for USP <800>, which requires external exhaust. These systems operate in tandem but biosafety cabinets are exhausted separately.

- Modular Zoning and Reconfiguration: Modular cleanroom infrastructure enables more agile implementation of this dual-compliance model. Walls, doors, airlocks, and environmental controls are precisely configured to ensure standards are maintained as operations evolve.

Operational Harmony: More Than Just Design

Of course, architecture alone doesn’t drive compliance—workflow, training, and culture do. Successfully operating a dual-standard facility means establishing SOPs that align with both USP chapters, training staff to navigate dual-use environments safely, and maintaining rigorous environmental monitoring and documentation.

The opportunity is clear: by integrating these systems, organizations don’t just comply—they become more efficient. Shared infrastructure, consolidated monitoring systems, and aligned training reduce duplication and increase visibility across operations. Instead of managing two silos, you manage one unified platform.

From Capital Constraint to Operational Agility

One of the most powerful outcomes of this shift is the ability to decouple cleanroom compliance from traditional capital planning. Instead of waiting years for funding, permitting, and construction, leading organizations are exploring on-demand access to compliant environments—whether to address regulatory gaps, support temporary production, or pilot new programs.

This model allows regulatory teams and facility managers to act with urgency when timelines tighten, audits loom, or standards evolve. It also supports a more sustainable, risk-aware approach to infrastructure investment—one where capabilities can be scaled up, down, or repurposed in step with business needs and regulatory direction.

Compliance as a Strategic Capability

Ultimately, the organizations positioned to lead in the age of USP <797>/<800> are the ones who treat compliance not as an obligation, but as a capability—a system they can deploy strategically, not just defend reactively.

They understand that flexibility, speed, and regulatory foresight are no longer luxuries, but are the foundations of safe, sustainable pharmaceutical compounding operations.

Rethinking Readiness

The future of regulatory compliance lies in mobility, modularity, and managed risk. Forward-thinking pharma and compounding leaders are already moving beyond traditional facility models, toward a more adaptive, resilient form of readiness built on modular infrastructure. The question isn’t just how to comply, but how to comply faster, smarter, and more sustainably than the competition.

Building Compliance into Your Strategy

As USP <797>/<800> standards continue to reshape the compounding landscape, the organizations that will lead are those that treat compliance as an adaptable, strategic capability. By moving beyond fixed infrastructure to flexible, modular solutions, facilities gain the agility to scale, reconfigure, and stay ahead of evolving regulatory expectations—all without the constraints of traditional capital projects.

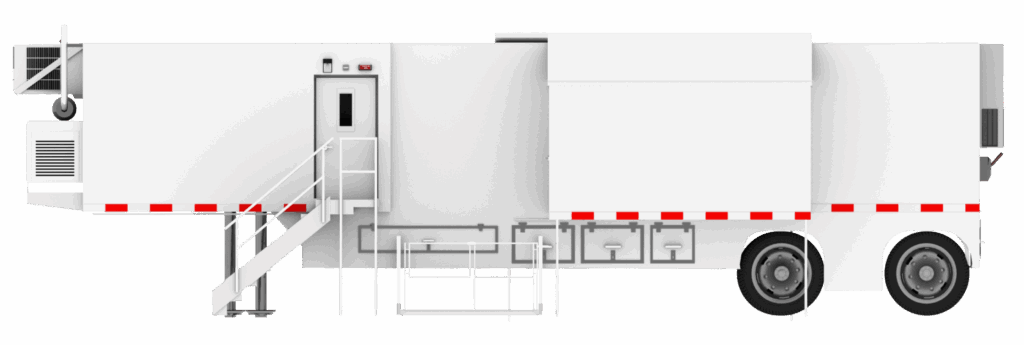

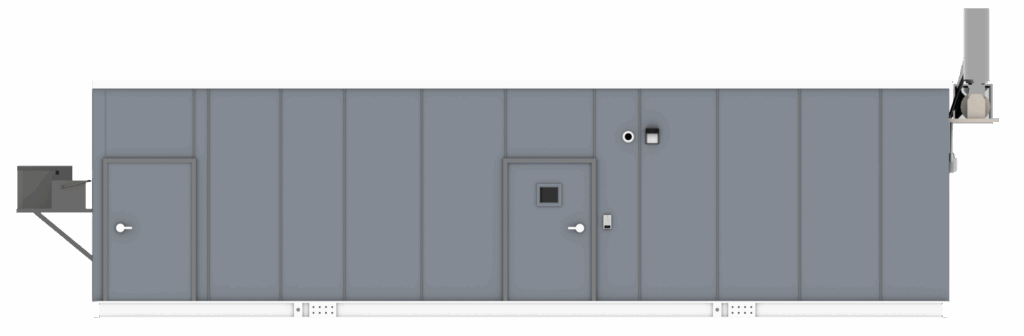

If you’re ready to rethink what compliance can mean for your operations, explore how Modular Devices’ fleet of leasable, self-contained pharmaceutical compounding cleanroom units can help you stay compliant, responsive, and future-ready.